Ana amfani da fasahar yin alama na na'ura mai alamar Laser da yawa a cikin filin bugawa, kuma ana amfani da na'ura mai alamar laser a cikin robobi, karafa, kwakwalwan PCB, kwakwalwan silicon, marufi da sauran kayan., Mechanical engraving, allo printing, chemical corrosion and other ways, with low cost, high volume, and za a iya sarrafa shi ta hanyar kwamfuta tsarin, yin zane-zane da kuma yin alama da graphics da rubutu da kake bukata, da kuma ƙarfin alamar samar da Laser. aiki a saman workpiece ne m Jima'i ne da fice fasalin.

A halin yanzu, a cikin masana'antar yin alama da bugu, injunan alamar laser sun mamaye fiye da kashi 90% na kasuwa.Dalilin da yasa injunan alamar Laser ke da irin wannan babban rabo shine saboda suna da fa'idodi 8 masu zuwa:

1. Dindindin:

Alamar na'ura ta Laser ba za ta shuɗe ba saboda abubuwan muhalli (taɓawa, acid da rage iskar gas, babban zafin jiki, ƙarancin zafin jiki, da sauransu).

2. Anti-jabu:

Alamar da aka zana ta hanyar fasahar yin alama ta Laser ba ta da sauƙi a kwaikwayi da canzawa, kuma tana da ƙarfin hana jabu.

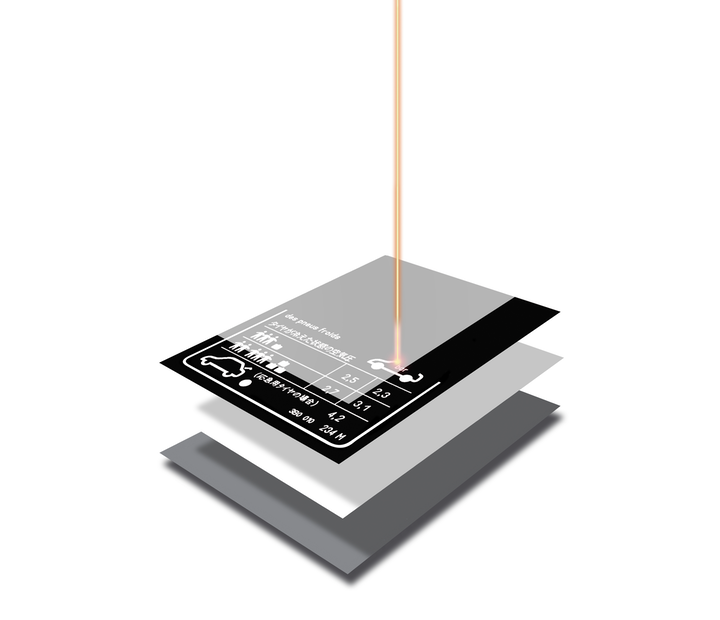

3. Mara lamba:

Ana sarrafa alamar Laser ta hanyar "wuka mai haske", wanda ba na injina ba, wanda zai iya buga alamomi akan kowane wuri na yau da kullun ko na yau da kullun, kuma kayan aikin ba zai haifar da damuwa na ciki ba bayan yin alama, yana tabbatar da daidaiton ƙarar kayan aikin.Babu lalata, babu lalacewa, babu guba, babu gurɓata yanayin aiki.

4. Faɗin aiki:

Na'urar yin alama ta Laser na iya sarrafa nau'ikan ƙarfe da kayan da ba na ƙarfe ba (aluminum, jan ƙarfe, ƙarfe, samfuran itace, da sauransu).

Kayan Filastik

Karfe Material

Kayan Gilashi

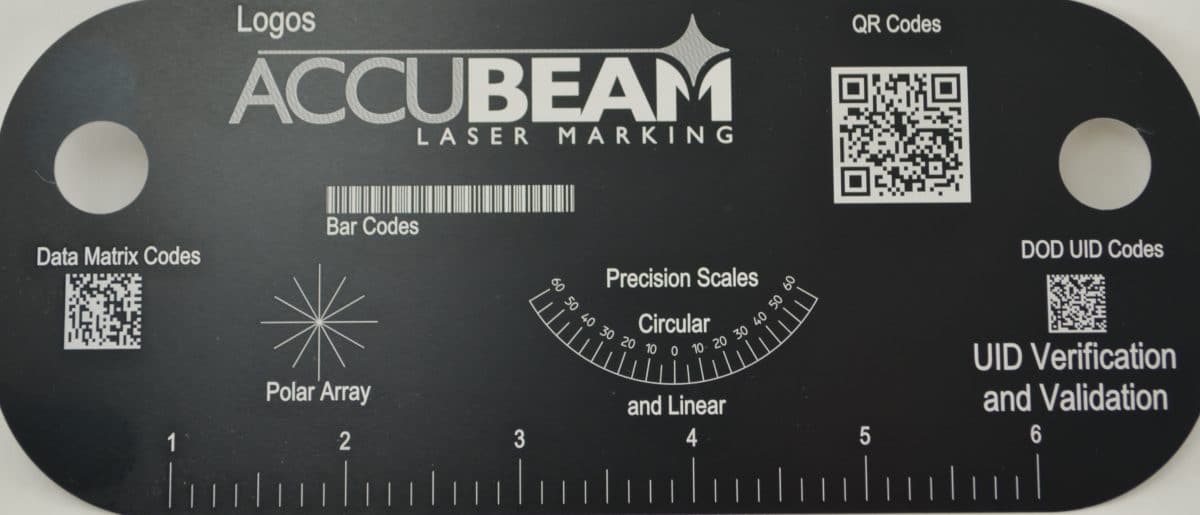

5. Daidaiton zane mai girma:

Abubuwan da na'urar sanya alama ta Laser ta zana suna da kyawawan alamu, kuma mafi ƙarancin faɗin layin na iya kaiwa 0.04mm.Alamar a bayyane take, dorewa da kyau.Alamar Laser na iya biyan buƙatun bugu da yawa na bayanai akan ƙananan ƙananan sassa na filastik.

6. Ƙananan farashin aiki:

Na'urar yin alama ta Laser yana da saurin alamar alama kuma an kafa alamar a lokaci ɗaya, tare da ƙarancin kuzari da ƙarancin aiki.

7. Babban aiki yadda ya dace:

Babban aiki yadda ya dace da saurin alamar alama.Laser katako a ƙarƙashin ikon kwamfuta na iya motsawa cikin sauri mai girma (gudun zuwa mita 5 zuwa 7 a sakan daya), kuma ana iya kammala aikin yin alama a cikin 'yan daƙiƙa kaɗan.

8. Saurin haɓakawa da sauri:

Saboda hade da Laser fasahar da kwamfuta fasahar, masu amfani iya gane Laser bugu fitarwa muddin sun shirya a kan kwamfuta, kuma za su iya canza bugu zane a kowane lokaci, wanda fundamentally maye gurbin gargajiya mold yin tsari, da kuma bayar da ga gajarta da samfurin haɓaka sake zagayowar da samar da sassauƙa.A dace kayan aiki.

Lokacin aikawa: Afrilu-20-2021